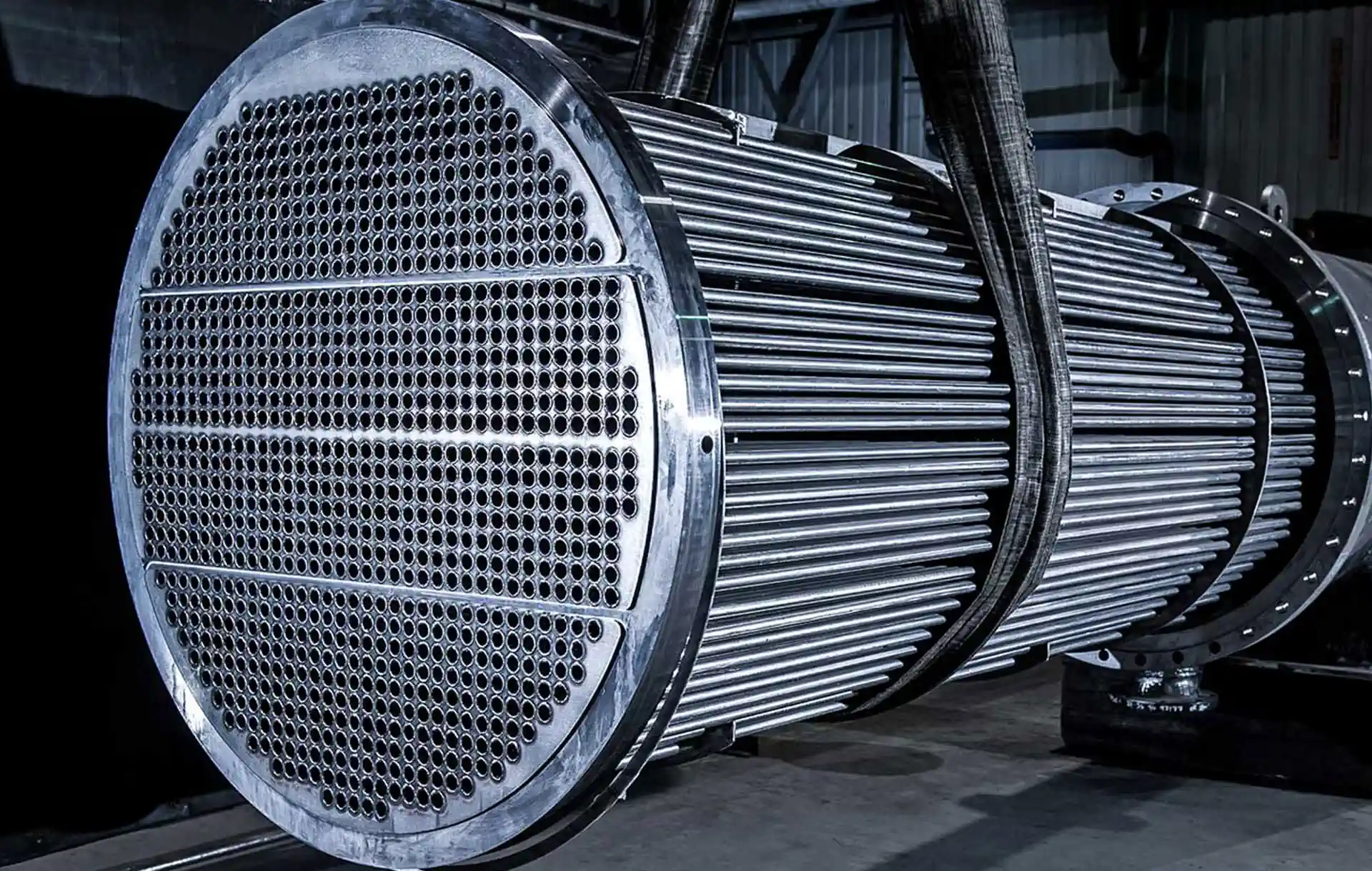

Pipes used in industrial steam and boiler systems operating at high temperature and pressure require a variety of steel grades (DIN 17175), dimensions and specially designed alloy and non-alloy steel pipes of extremely high quality and suitable for the conditions of use.

Seamless steel drawn tubes are preferred for boiler and steam systems, especially under high-risk operating conditions and when operational reliability must be ensured.

Used in super heater and heat exchangers in boilers that can operate up to 750 °C, min. 1/2″ diameter pipes manufactured using St 35.8, St 45.8, 15M03, 13CrMo44 and 10CrM910 quality steels in accordance with DIN 17175 standard.

Characteristics of boiler and steam pipes

- High strength: Seamless steel boiler and steam tubes are durable and long-lasting because they are made of high-strength steel.

- High temperature resistance: These pipes have high temperature resistance as they are used in systems operating at high temperatures.

- Chemical resistance: Seamless steel boiler and steam tubes can be designed to withstand a variety of chemicals.

- Precise dimension: These pipes are manufactured with high precision, which ensures tightness and accurate installation. 5. Good corrosion resistance: These pipes are made of steel

- is resistant to corrosion because it is made of corrosion-resistant material.

- High pressure resistance: Boiler and steam (DIN 17175) pipes have high compressive strength because they are used in high-pressure systems.

- Wide range of production: These pipes can be manufactured in different sizes and thicknesses, making them suitable for different applications.

Usage Places of Boiler and Steam Pipes;

- Biomass Combustion and Fuel Systems

- Steam Boilers

- Pressure Vessels

- Heat Boilers

- Industries Requiring High Temperature

- Thermal Oil Boilers

- Filtered Chimney Systems

- Steelworks

- Ovens

As a result, in line with differentiating needs, our first priority is to keep seamless steel pipes in our stock, certified to the appropriate standards.

it was founded on 03.01.2023 in Gaziantep. Engineering solutions for steam, fire, water systems.

Quick Menu

Our Products

Contact

-

Beylerbeyi, 84027 Nolu Sokak No:11/G, 27000 Şehitkamil/Gaziantep

-

info@zenteknik.com

-

+90 342 502 58 91

-

+90 552 881 97 27

© 2024 Zen Teknik Engineering Tüm Hakları Saklıdır. | Gizlilik Politikası

Web Design Digital Küre